Types of Cabinet Door Router Bit Sets

Creating beautiful, custom cabinet doors hinges on choosing the right router bit set. The variety available can seem overwhelming, but understanding the different types and their applications simplifies the process and leads to stunning results. This guide will help you navigate the world of cabinet door router bits, ensuring you select the perfect set for your project.

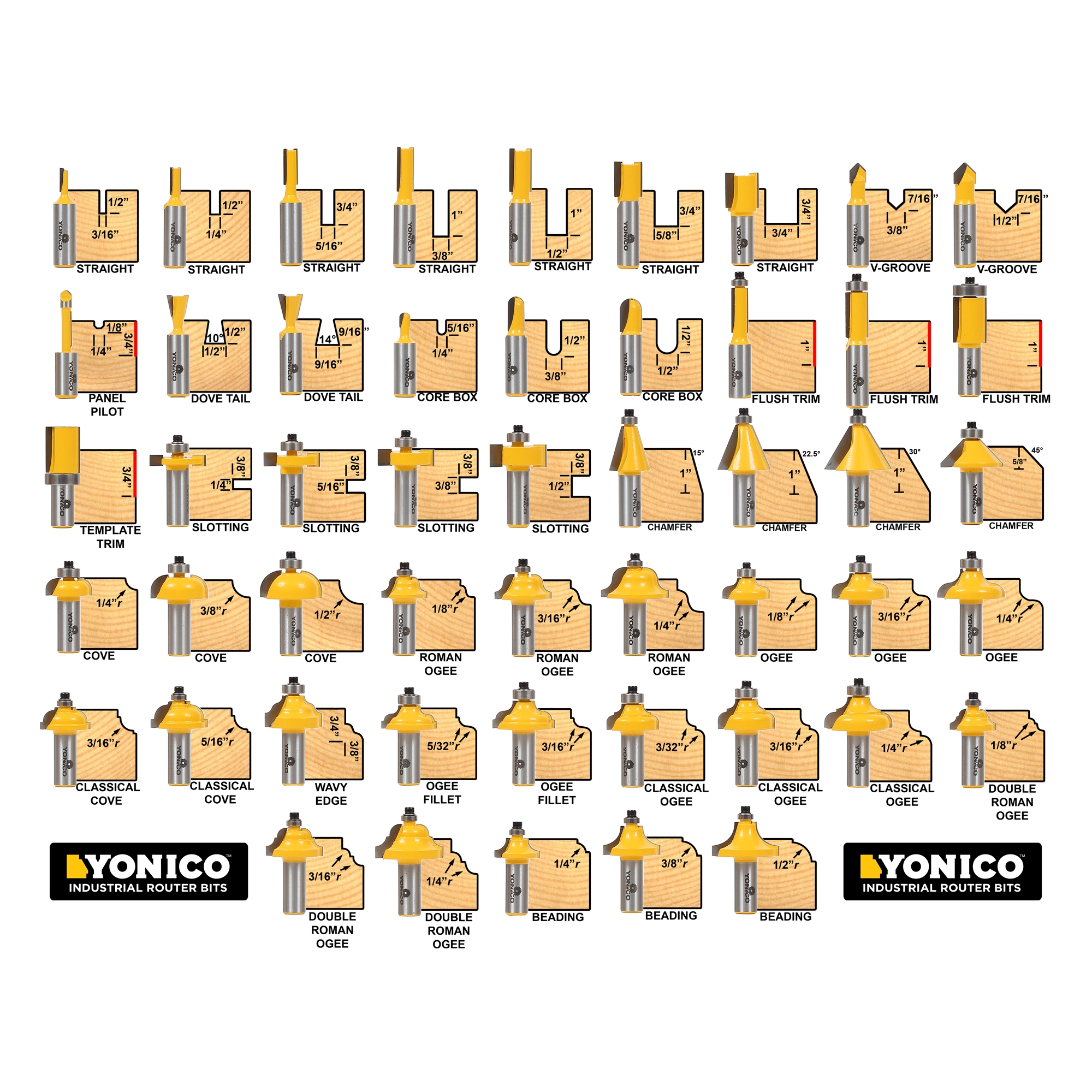

Cabinet Door Router Bit Profiles

Cabinet door router bits are categorized primarily by the profile they create. These profiles determine the overall look and style of your finished doors. Common profiles include raised panel, flat panel, and ogee. A raised panel bit creates a recessed area around a raised center panel, offering a classic and elegant look. Flat panel bits produce a smooth, flat surface, ideal for contemporary designs. The ogee profile features a graceful, S-shaped curve, adding a touch of sophistication. Other profiles, such as beaded or cove, provide further stylistic options.

Router Bit Shank Sizes and Materials

Router bits come in various shank sizes, typically 1/4 inch or 1/2 inch. The shank size must match your router’s collet capacity. The material of the bit significantly impacts its performance and lifespan. High-speed steel (HSS) bits are a more affordable option, but they tend to dull more quickly than carbide-tipped bits. Carbide-tipped bits are significantly more durable, offering a longer lifespan and cleaner cuts, particularly when working with hardwoods. They are more expensive initially, but their longevity often makes them a more cost-effective choice in the long run.

Comparing Router Bit Materials: Carbide vs. High-Speed Steel

Cabinet door router bit set – Carbide-tipped router bits are known for their exceptional durability and sharpness retention. They can withstand significantly more use than HSS bits, making them ideal for large-scale projects or working with harder woods. However, they are more expensive. HSS bits, while less durable, are a more budget-friendly option for occasional use or smaller projects. The choice often depends on the frequency of use and the type of wood being worked with.

Selecting the Appropriate Cabinet Door Router Bit Set

Choosing the right bit set depends on several factors. The following table provides a guide:

| Door Style | Wood Type | Recommended Bit Type | Considerations |

|---|---|---|---|

| Raised Panel | Hardwood (Oak, Maple) | Carbide-tipped Raised Panel Bit (1/2″ shank) | Hardwoods require durable bits; larger shank for stability. |

| Flat Panel | Softwood (Pine, Fir) | Carbide-tipped Straight Bit (1/4″ shank) | Softwoods are easier to cut; smaller shank is sufficient. |

| Ogee | Hardwood (Cherry, Walnut) | Carbide-tipped Ogee Bit (1/2″ shank) | Complex profile requires a durable, precise bit. |

| Beaded | Medium Density Fiberboard (MDF) | HSS Beaded Bit (1/4″ shank) | MDF is relatively soft; HSS bit is suitable for occasional use. |

Using Cabinet Door Router Bit Sets

Working with cabinet door router bit sets can transform ordinary wood into beautiful, functional pieces. However, safety and precision are paramount. Understanding the proper techniques and observing safety precautions will ensure both a successful project and a safe working environment. This section will guide you through the process, from setup to the final touches.

Safe Practices and Techniques

Safe operation of any power tool requires careful attention and adherence to safety guidelines. Ignoring these can lead to serious injury. Remember, woodworking is a rewarding craft, but it demands respect for the tools and materials. Always prioritize safety.

- Always wear safety glasses to protect your eyes from flying debris.

- Use hearing protection to safeguard your hearing from the noise generated by the router.

- Ensure the workpiece is securely clamped to the router table or jig to prevent movement during operation.

- Never reach across the spinning router bit. Always wait for the bit to come to a complete stop before making adjustments or removing the workpiece.

- Use push sticks and featherboards to keep your hands a safe distance from the router bit.

- Inspect the router bit for any damage before each use. Replace damaged bits immediately.

- Maintain a clean and organized workspace to minimize the risk of accidents.

- Disconnect the router from the power source before making any adjustments or cleaning.

Routing Cabinet Doors Using a Router Table

A router table provides exceptional control and consistency when routing cabinet doors. The key is in setting up a suitable jig to ensure accurate and repeatable cuts. A well-designed jig can save time and reduce the chance of errors.

Imagine a simple jig: A sturdy piece of plywood with a precisely cut opening that matches the size and shape of your cabinet door. The door is placed within this opening, allowing for consistent positioning relative to the router bit. Clamps secure the door firmly in place. This ensures that each door receives the same routing profile. Different jigs can be designed for various door sizes and profiles. The jig acts as a guide, eliminating guesswork and resulting in professionally finished doors.

Routing Techniques for Various Cabinet Door Profiles, Cabinet door router bit set

Different cabinet door profiles require different routing techniques. Let’s consider a raised panel door as an example. First, the panel is carefully positioned in the jig and secured. The router, fitted with the appropriate bit, is then used to create the profile on the edges of the panel. The feed rate should be consistent and slow to avoid tear-out. Once the edge is routed, the panel can be removed from the jig, and the process can be repeated for other doors. Similar techniques, adapted for the specific bit and profile, apply to other styles like shaker doors or flat panel doors. Smooth, even pressure and careful attention to detail are key to achieving a professional finish.

Cabinet Door Design and Router Bit Selection

Choosing the right router bits is crucial for creating beautiful and functional cabinet doors. The style of your door dictates the bits you’ll need, impacting both the aesthetics and the overall strength of the finished piece. Let’s explore how design influences bit selection.

Cabinet Door Styles and Corresponding Router Bit Sets

Cabinet door design offers a wealth of creative possibilities. The selection of router bits directly impacts the final look and feel. Here are three distinct styles and the ideal bit sets for each:

1. Raised Panel Door: This classic style features a recessed panel surrounded by a raised frame. The clean lines and timeless appeal make it a popular choice.

Ideal Router Bit Set: This design requires a set including a raised panel bit (for creating the recessed panel), a straight bit (for cutting the frame), and possibly a cove bit (for adding decorative detail to the frame). The raised panel bit’s size will determine the depth and width of the panel recess, while the straight bit’s width defines the frame’s dimensions. A cove bit adds a subtle curve to the frame’s edge, enhancing its visual appeal.

2. Flat Panel Door with Beadboard Detail: This style showcases a simple flat panel with added texture and visual interest through beadboard detailing.

Ideal Router Bit Set: A straight bit is essential for cutting the flat panel and its frame. To create the beadboard effect, you’ll need a beading bit, which carves a series of small, raised beads along the panel’s edges. The size and spacing of the beads are determined by the beading bit’s profile. This approach results in a more detailed and visually rich door than a plain flat panel.

3. Shaker Style Door: Characterized by its simple, clean lines and absence of ornamentation, the Shaker style emphasizes functionality and understated elegance.

Ideal Router Bit Set: A straight bit is sufficient for creating the Shaker door’s frame and panel. However, a small, decorative router bit such as a chamfer bit can be used to soften the edges of the frame and panel, adding a touch of subtle detail without detracting from the door’s minimalist aesthetic. This subtle detail enhances the overall visual appeal without sacrificing the clean lines that define the style.

Common Mistakes When Using Cabinet Door Router Bits

Working with router bits requires precision and care. Here are some common pitfalls and how to avoid them:

Using dull bits is a frequent error. Dull bits tear the wood, creating rough edges and potentially damaging the router itself. Regular sharpening or replacement of your bits is essential for achieving clean, precise cuts.

Always inspect your router bits before each use. Replace any dull or damaged bits immediately.

Incorrect bit depth settings lead to inconsistent results. Precise depth control ensures consistent cuts and prevents errors. This is particularly important when creating raised panels or intricate details.

Use a depth gauge or adjustable stop collar on your router to ensure consistent bit depth.

Improper feed rate (the speed at which you move the router across the wood) can cause chipping or burning. Too fast a feed rate can lead to burned wood and a rough finish, while too slow a feed rate can result in tear-out. Experiment to find the best feed rate for your router, wood type, and bit.

Maintain a consistent feed rate during routing. Practice on scrap wood to find the optimal speed for your tools and materials.